Immersive technologies use augmented or virtual reality to provide additional information or enable simulations.

Virtual Reality (VR) can visualize objects or buildings through 3D models or photographic methods such as photogrammetry. It enables users to navigate virtual environments and modify or enhance them.

At SPIE, we use VR to create digital twins of equipment, technical rooms, or entire buildings. Beyond the visual component, we enhance digital twins with additional static information such as plans and link equipment to their corresponding system data (e.g., from CAFM systems). We transform dynamic operational data (e.g., from sensors) into a virtual representation of the physical asset. To create digital twins, we utilize 3D laser scanning technology.

This results in a 3D photographic capture combined with a so-called point cloud, which enables accurate measurement within the scan. The more precise the 3D laser scan, the more accurate the measurements. In a subsequent step, a 3D model can be drafted based on the point cloud.

In numerous cases, a 360-degree capture provides sufficient accuracy to meet the requirements of our use cases. In collaboration with our partner FARO, we are also able to generate precise 3D documentation through 360-degree camera walkthroughs.

VR is also used at SPIE for training purposes. We have already reported on this approach in previous digitalization reports. Based on 3D models, we have independently developed specific use cases such as “Maintenance of a Ventilation System.” With the growing range of offerings, we are increasingly relying on standardized training programs as well, for example, the “Five Safety Rules.”

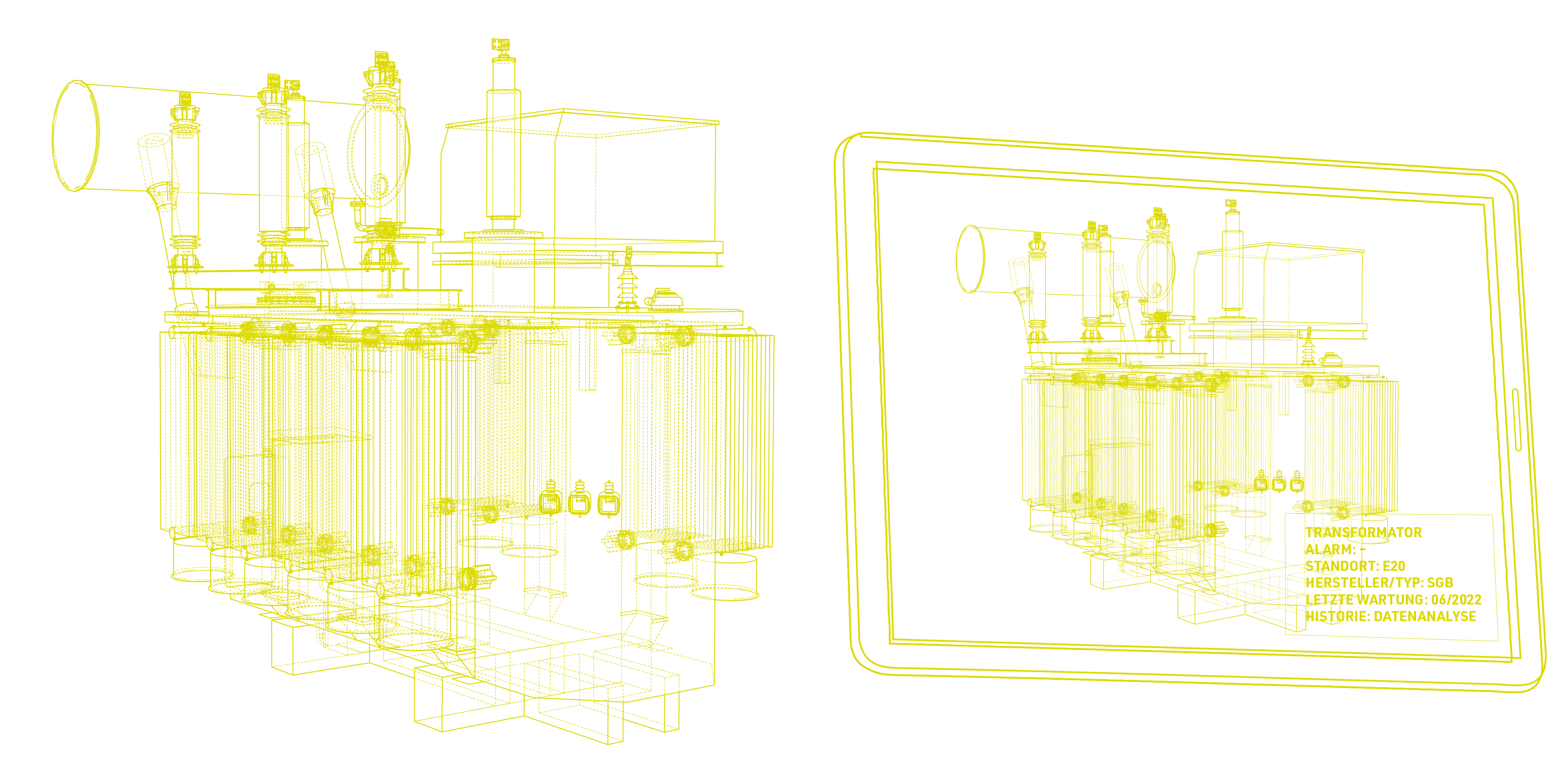

Augmented Reality (AR) applications enhance the real-world view by overlaying digital information. For example, sensor values can be displayed directly on the equipment. So far, we have primarily used AR for remote support use cases. Through digital communication combined with 3D capturing, third parties can gain a view of the equipment. Virtual markers in the real-world view ensure precise and unambiguous communication. We have tested various smart glasses for this purpose and already use software products proven on smartphones and tablets. With the increasing user-friendliness of smart glasses, we observe improved acceptance among our colleagues and are now planning initial deployment scenarios.