Research and Technology Center

expertise

Our experts have been consulting you with their extensive expertise since the institution was founded in 1969.Your partner for testing and evaluation of high-voltage components

Since we were founded in 1969, we have built up an extensive know how and have been acting as a partner for research and development projects with our testing capabilities for over 50 years. Our work on standardization committees and a large number of publications in partnership with our customers are proof of our professional expertise.

Inspection

We carry out extensive on site inspections and damage analyses on overhead power lines and substations. Our customers receive comprehensive recommendations on how to deal with detected anomalies. Training

Training

We offer basic training on overhead power lines and their components to our customers as well as basic training for linesmen.

accredited

As an accredited testing institution, we guarantee independent and comprehensive quality control. You can find our accreditation certificate and the list of our test standards under “Downloads”.

Testing infrastructure

Your benefits

The international recognition of the work carried out by the Research and Technology Center is primarily based on the qualifications and experience of our team and our center’s outstanding technical equipment. Thanks to the ongoing training of our experts, we will continue to be your strong partner in the future.Testing services

Manufacturer-independent type tests and comparative analyses

Selected examples of standard testing services:

Inspections and condition assessments

Solutions tailored to our customers’ requirements

FROM LARGE-SCALE TESTING TO MICROANALYSIS

The Research and Technology Center is a strong partner, when it comes to both basic tensile testing and the coordination of multiple testing institutes working together on research programs. In addition to the testing laboratory, a 400-metre-long outdoor test area with a 16 meter high portal is available, and we can construct test set-ups up to ten meters high.

Development of power supply components, modules and complex systems

Training and education

• Field reports on anomalies, damages and new developments

Training for employees in the power supply industry and for linesmen

Both our knowledge of component testing and our expertise in various aspects of overhead power lines make us a reliable partner for your research and development projects. We support all project phases, from problem description and brainstorming, to concept creation, feasibility and profitability studies, until implementation and evaluation of technical innovations.

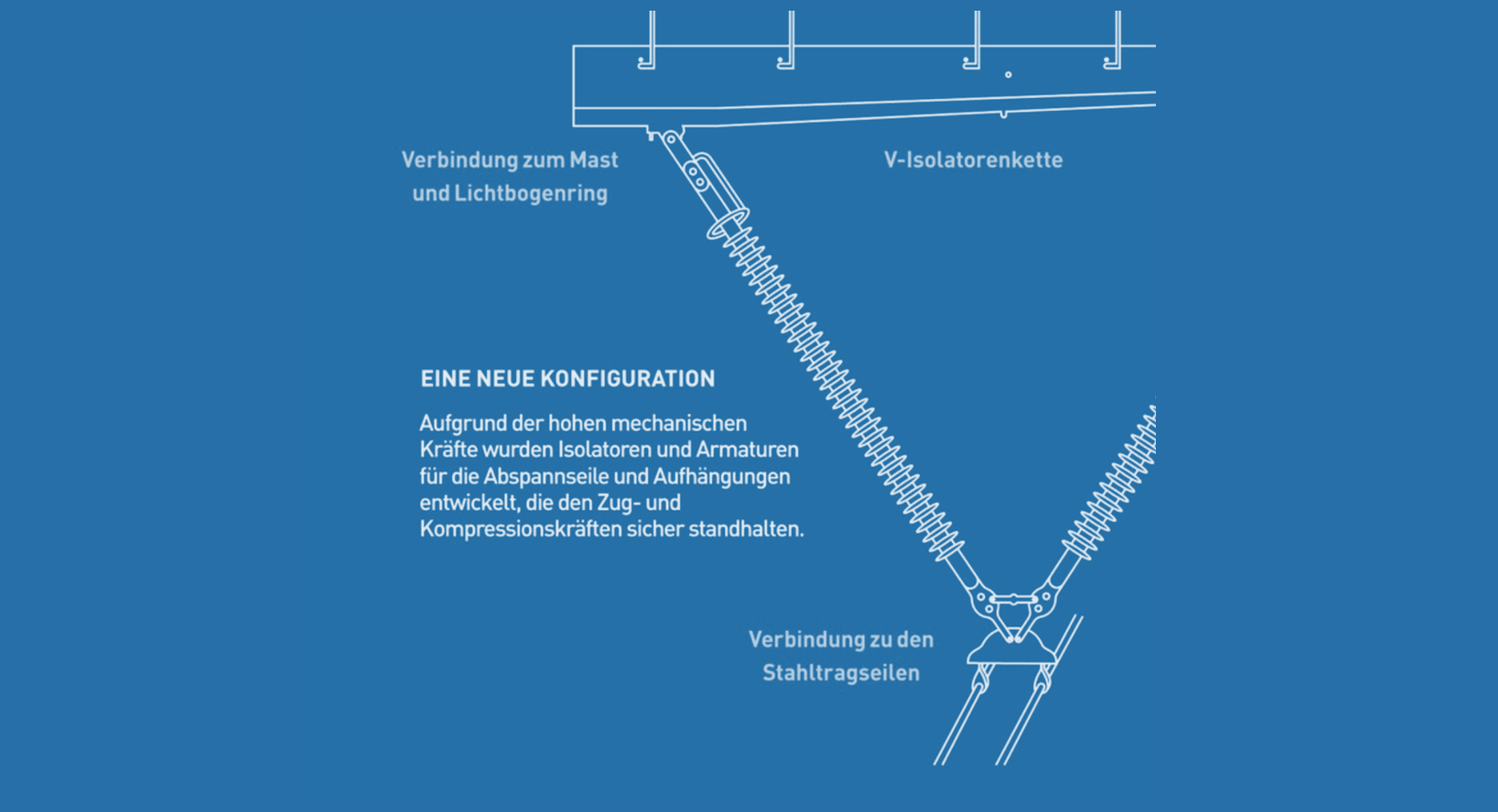

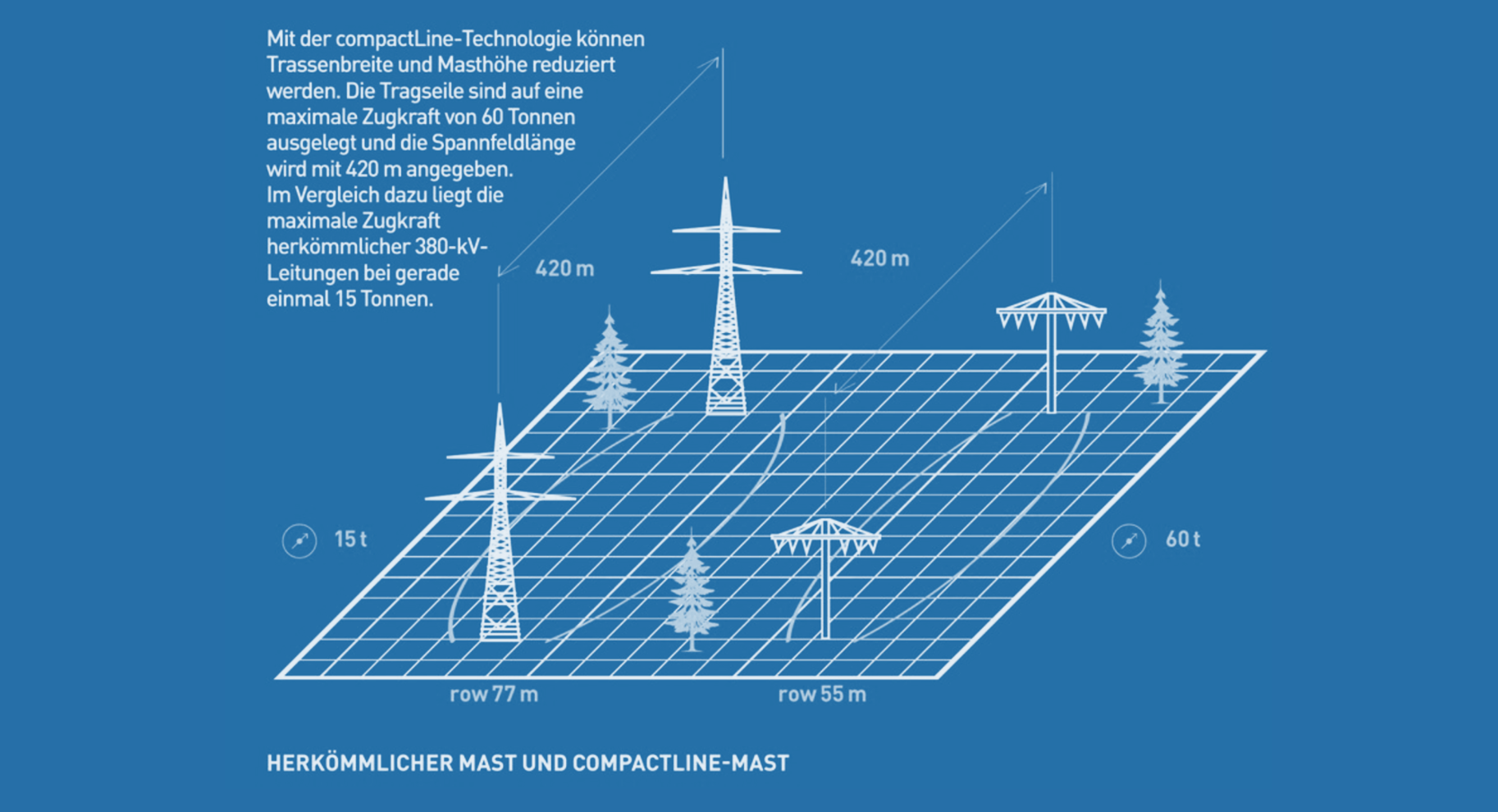

High transmission capacity delivered through narrow lines

The idea behind compactLine is as spectacular as it is unspectacular. The bundle configuration of conductors is supported by two tightly tensioned steel cables (like in cable cars or bridges), which significantly reduces the sag. New conductors for greater power output can be attached to these steel cables, resulting in fewer towers and narrower lines. At the same time, compactLine increases the transmission capacity of a conventional high-voltage power line from 220 kV to 380 kV.

An additional advantage:

With their pioneering design, new power lines also satisfy aesthetic requirements, as the more compact arrangement enables that the pylons and power lines are perceived as less obtrusive. This means new lines are more likely to be accepted by the public, making it easier for utilities to obtain the necessary permits for the construction of more powerful overhead power lines.

The innovative overhead power line technology compactLine is becoming reality. From 2013 to 2016, SPIE undertook research into the development and testing of compactLine as part of the research consortium founded by 50Hertz. At the end of August 2018, a pilot section of the innovative compactLine overhead power line technology was commissioned in the eastern part of Saxony-Anhalt in Jessen (Elster).

Thank you for your interest in the Research and Technology Center. We look forward to hearing from you.